Excellent Introduction On Electric Bikes Corresponding to Stark Drives Development

There is no shortage of information on the technology behind electric bikes and the two main systems that are most popular in the marketplace today. This being Torque based Mid Motor drives and Hub Motor based electric bikes. The primary determining factor for the average consumer has been the price difference between these two technologies due simply to competition in the (producers) marketplace and the number of manufactures producing these two types of systems.

The most common and widely produced systems currently in production are hub motor drive systems with literally hundreds of manufacturers production these well developed and refined electronic systems which in turn helps to drive prices down on this technology to the benefit of the consumer. Much less competition exists in mid motor drive circles with just a handful of manufacturers that exist and due to the reality that each of these manfuactuers have invested significant R&D capital into their systems these underlying mid motor systems are typically much more restrictive with the manufacturer of a mid motor requiring companies that use their systems to take not only the mid motor but a whole host of other components which work in tandem to ensure the system functions.

For example with a hub motor based motor, typically one can purchase the motor from one manufacture, a controller from an unrelated manufacture and so on to build a finished product which is not the case with mid motor drive manufacturers. Having Built Stark Drive Torque, we know first hand that the only components we had levy to made decisions over were all non electrical components with even the exclusion of the crankset as this was provided from Bafang as set with their mid motor drive.

Ultimately as more manufacturers enter the mid drive motor market and competition escalates in this style of motor drive, prices will naturally fall but the time being the performance gains that exists with this style of motor have historically been for early adopters whom were willing to pay more for the latest available technology.

At Stark Drive we are doing our (small) part to help drive prices down by bringing electric bike technology to the consumer without all the markups typically associated in the e-bike industry and the (up to now) standard practice of middleman after middleman each taking a cut with the eventual consumer having to pay an inflated cost which serves to hinder marketplace adoption and affordability of electric bikes.

We launched Stark Drive in 2017 for an unbelievable starting price of $399 and Stark Drive Mini (Gen1) for only $299. We even worked to launch Stark Drive Torque which was the first torque based bafang mid motor drive for unheard of pricing.

We plan on relaunching Stark Drive Mini (Gen2) with upgraded specifications, more powerful power system (to 48V) which will give the consumer more hill climbing and towing power and to relaunch Stark Drive Torque once we finish testing the Gen3 prototype which we expect to receive very soon with all the integrated tech that we have discussed on previous blog posts about this very powerful and feature loaded electric bike.

We see 48V as the future of Stark Drive along our entire line and will slowly be making the shift to this power level. In fact for those that ordered our RAD Power Upgrade at 750W they have already experienced the 48V systems on our original Stark Drive and this is available even today when customizing your bike on our website.

Sincerely

Stark Drive Team

Stark Drive LLC

How Does Stark Drive Torque Max Compare to the Competition?

Stark Drive Torque Max - $1999

Vs

The EVELO Aries Mid-Drive is priced at $3,499.

An excellent review on The Evelo Aires Here: https://electricbikereport.com/evelo-aries-mid-drive-electric-bike-review-part-1-pictures-specs/

Stark Drive Torque will be launching on Indiegogo August 20, 2019 at 12:00 PM EST.

Sincerely

Stark Drive Team

Stark Drive LLC

Stark Drive Torque Launch - August 20th 12PM EST

Title says it all, the first backers will get the early bird Stark Drive Torque.

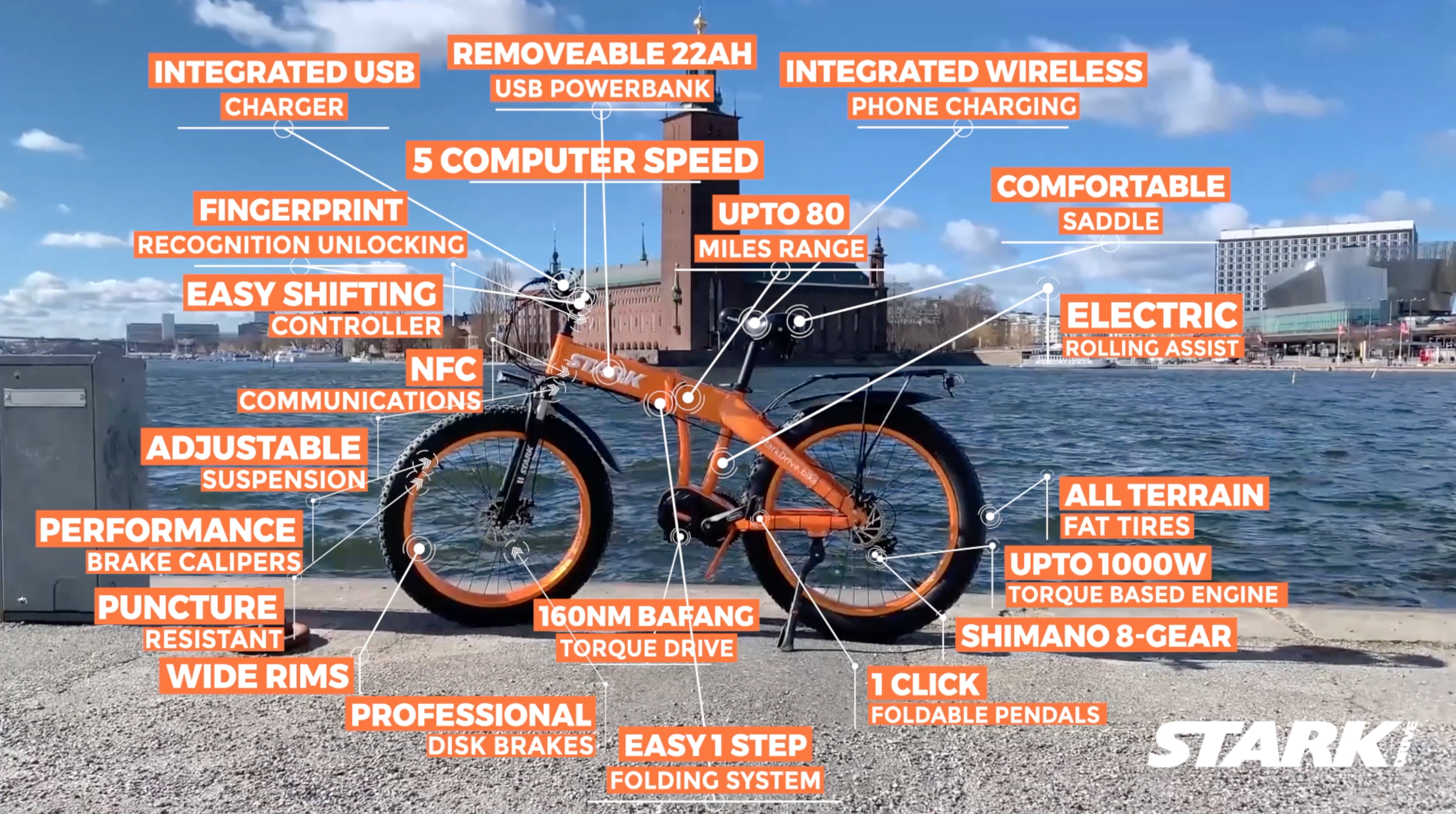

Stark Drive Torque can be configured in dozens of ways including fingerprint recognition or even up to 1000W engine. The first Mid Motor Torque Based Folding electric bike

Stark Drive Torque:

Stark Drive Torque Max:

We are really excited to be launching what has proven to be one of the biggest challenges our company has undertaken to date.

Sincerely

Stark Drive Team

Stark Drive LLC

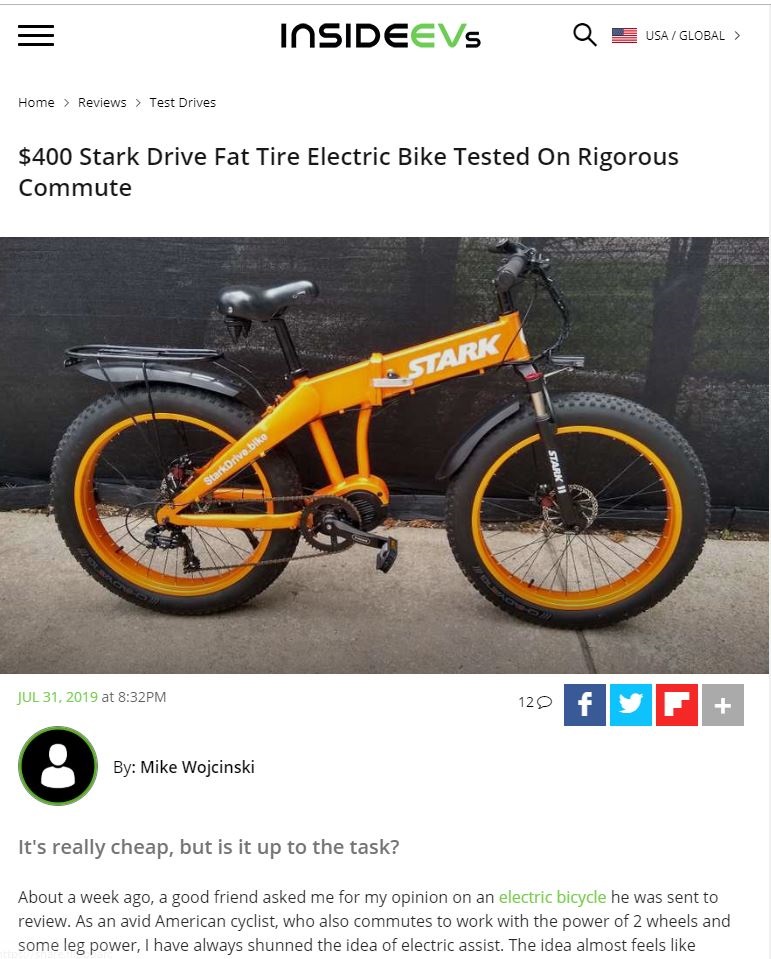

Stark Drive Torque Max Reviewed by InsiderEVs.com!

Hello,

we are pleased to announce a review by the respected online publication in all things electric: InsideEVs.com.

https://insideevs.com/reviews/362810/stark-drive-electric-fat-tire-bicycle-review/

It worth noting that all we had available to send to them was the Block 1 or Version 1 of Stark Drive Torque, there have been countless improvements to the Block/Version 2 Model which we talk about in earlier blog posts with photos. When designing a bike from the ground up including the frame, there are always challengs that must be overcome and we have worked to improve every aspect of the bike and will continue to do so for our upcoming August Launch on Indiegogo.

Sincerely

Stark Drive Team

Stark Drive LLC

Stark Drive Torque Behind the Scenes - Manufacturing Partnerships

I wanted to bring you a short video update on the process behind how we manufacture Stark Drive Torque filmed on location in beautiful Hong Kong. As you can probably tell during the video it was incredibly warm and humid there and my frame was built for colder weather so please excuse my attempts to wipe the sweat off my forehead during the video.

Stark Drive Mentioned on Japanese Publisher Bouncy.News

Stark Drive has been featured with Japanese based Bouncy.News below.

We are pleased to have been covered and look forward to delivering the most affordable mid motor torque based folding electric bikes in the world launching August 2019!

Register today to get the launch email for torque drive electric bike at www.starkdrive.world.

Stark Drive Torque Review by Computerbild.de

With just weeks till our launch of Stark Drive Torque on Indiegogo, we are super pleased to have been reviewed by the respected publication Computerbild.de here:

https://www.computerbild.de/artikel/cb-Tests-Freizeit-Stark-Torque-Check-Klapprad-23654963.html

For all you german speakers there has been a video review done here below:

And for those that do not speak german, the article seems to translate very well when using any online translation enabled browser such as Google Chrome.

Just a note that this review was done of our block 1 prototype and we have already improved and enhanced Stark Drive Torque to block 2 which has a number of feature improvements and upgrades as can be seen on our blog post below:

https://starkdrive.bike/blog/stark-drive-torque-manufacturing-and-development-part-1/

https://starkdrive.bike/blog/stark-drive-torque-manufacturing-and-development-part-4-coatings/

Stay tuned to our blog for further updates about the manufacturing process of Stark Drive Torque that we will release in the coming days.

We want to extend a thank you to Christian Hensen at computerbild for taking the time to review the EU legal version of Stark Drive Torque - the most affordable mid motor torque based folding electric bike in the world.

Sincerely

Stark Drive Team

Stark Drive LLC

Stark Drive Torque Manufacturing & Development: Part 4 Coatings

When we produced the V2 prototype of Stark Drive Torque (SDT) and Stark Drive Torque Max we knew it was something special and wanted it to stand out. Therefore decided to go for hydro graphics instead of simply painting the frame as we have done in the past.

On our visit to our coatings partner, we spent some time discussing what we were after as well as how we wanted torque to be perceived as the number of types of hydro graphics designs are literally infinite, at his factory, on hand he had over 2500 styles with a warehouse and access to an additional 100.000 styles

The process to apply a hydrographic is not especially difficult but that does not mean that it does not take exceptional skill, especially when the shape is as complicated as the frame for SDT. On our first attempt in fact, the shape and size was somewhat underestimated and resulted in an incomplete coating. As you will see below in our video we had to then clean, dry and repaint the bike base coat so that it could be coated again with the design. The second attempt was much more successful as you can see from the final photos.

When we go into mass production, those whom opt for a hydro graphic coating instead of painting, the process will not be done by hand, instead it would be done by machine to ensure a consistent result and accurate repeat-ability.

I describe the process in the videos below however basically these work as follows:

- frame is prepared with a base coat of paint of any color, this base coat would then show through any transparent sections of the hydro graphic.

- hydro graphic design is prepared and released from its backing

- Component is slowly dipped into the hydro graphic bath so that the design wraps around the component

- component is removed carefully from the bath such that no overlap of patten transfers

- component is washed and sprayed with a final coat to seal in the design

The process is arguably faster than regular painting and gives you the ability to add some very wild and unique designs to your bike. we will be offering a limited number of these during our launch of Stark Drive Torque on Indiegogo when we launch in August 2019.

The final result you can see below, it looks quite striking:

SIncerely

Stark Drive Team

Stark Drive LLC

Stark Drive Torque Manufacturing & Development: Part 3 Fingerprint Recognition

Fingerprint Recognition on an Ultra Affordable eBike

One of the coolest features we have worked hard to include for the upcoming Stark Drive Torque (SDT) platform is fingerprint recognition technology. This is a feature that is normally found in ebikes that are several times the cost of our planned pricing for SDT. Fingerprint recognition would allow you to forgo having to carry around a key for the bike in order to use the electrical assist features and also enable you to share the bike with friends and family whom have registered their respective biometrics with the bike.

The power system on SDT instead of being controlled solely with the key can now be controlled simply by using your fingerprint to turn the bikes power system on and off at your leisure. As always all of this tech is hidden from sight inside the bike frame, something we were able to accomplish due to our use of the new Bafang line of Torque Mid Drive motors which house both the motor and controller right inside the drive system located centrally weighted on the bike. This left us with a lot of room in the frame to add features such as biometrics to control the bike.

We are not the first to include such tech on our bikes. A notable ebike already on the market by Van Moof already includes this tech but for a base price that is triple the cost of SDT. As always our company's mantra was and still is to make accessible the best technology that the electric bike revolution has to offer at a cost that makes it accessible to anyone that wants to own it.

Stay tuned for our next blog posting talking about even more unique features that will be available on the upcoming SDT!

Sincerely

Stark Drive Team

Stark Drive LLC

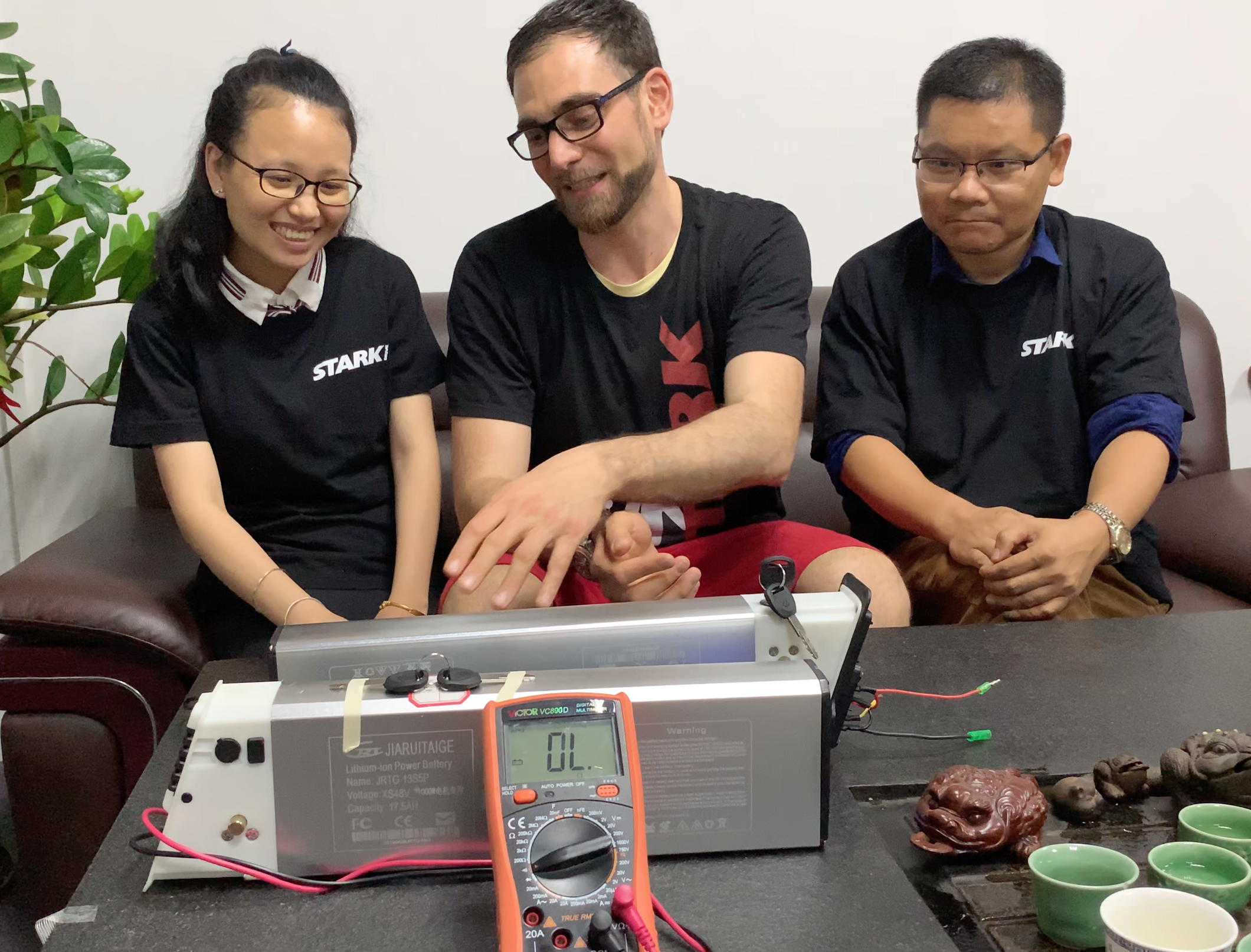

Stark Drive Torque Manufacturing & Development: Part 2 Battery Factory

The whirlwind visit to our various factories in china also included a visit to our exclusive battery manufacturing partners whom we have been working with since the launch of the original Stark Drive back in 2017. This factory has been manufacturing ebike batteries for over a decade and has a great deal of experience when it comes the technology behind a perfectly designed and long lasting battery pack.

A battery pack is not simply just a bunch of cells connected in series and parallel and in fact has a lot of circuitry and software that continually senses the state of the battery pack making sure that the cells do not discharge past their safe limit and that the cell charging cuts off to prevent any over voltage situation for the cells, which can prematurely shorten the life of the pack.

Volts

The battery cells for Stark Drive Torque (SDT) will be imported from Japan and will use the best high capacity cells available which currently include cells from Panasonic, Samsung or LG. We use 18650 cells of varying capacity in order to achieve the rated Ah rating that on the pack. We will be offering three battery capacities for Stark Drive Torque that include 9Ah, 13Ah and 18Ah which will operate at the matching voltage to the bike. It's interesting to know that as you increase the bike systems voltage from 36V to 48V and so on, that you need to add a the equivalent corresponding number of cells in series to achieve the desired voltage. For example, if you needed to achieve a total of 36V using our cells, you would need 10 cells in series, conversely, if you wanted to get up to 48V you then need 14 cells in series.

| 10 | 37.0V |

| 14 | 51.8 V |

Remember though that the actual voltage of your battery will be both higher and lower than the nominal voltage during the discharge cycle. To get the full voltage of a battery when fully charged, multiply the fully charged voltage of each cell (4.2 V for li-ion) by the number of cells. So a 10s battery pack is actually 42.0 V when fully charged. The fully drained voltage would be approximately 3.0 V multiplied by the number of cells in series, which would be 30 V for a 10s pack. Our protection circuitry to prevent under voltage cuts the battery off at 27V meaning that the bike stops working as an electric bike when it drops to near this voltage and in fact if you leave your pack sitting over the winter not having charged it the battery would then go into protection mode and the default charger that we ship with Stark Drive will no longer charge the pack and a special charge is needed. In actuality, most li-ion cells can be drained down to 2.5 V, but there is very little energy left between 3.0 V and 2.5 V and it is healthier for the cells to stop discharging at 3.0 V.

Amps

In order to get the desired Ah rating on the pack, you then have to take groups of these series connected cells and connect them in parallel to reach the desired rating. It then becomes the physical space inside the battery housing that determines what the total Ah rating is on the pack as there is physically only so much space available inside the battery housing. If you wanted a 17Ah battery pack at 48V you would need a housing that is roughly 40% larger than the equivalent 36V pack.

Features and Upgrades

Just as we have with the frame, we have redesigned the battery pack for SDT from the ground up adding both a protective fuse to prevent any damage to the cells no matter if they are in use or during charging as well as a unique USB (fast charging) out enabling you to use the battery pack independently of the bike as a high capacity powerbank no matter where your adventures may take you be it a ride through the city or an excursion off road.

Fingerprint recognition

As we are adding fingerprint recognition to the bike, we are reworking the battery pack keying system so that the key can be removed with the bike on (not the same style as the original Stark Drive). This means that the bike can be left on and the bike can be activated by any previously registered fingerprint meaning you can share the bike with the family or friends. There is a USB port built into the frame to access the fast charging capability on the battery pack as well as one located in the bike computer, one can never have enough USB ports when on the road. The battery locks into the frame just like it did with the original Stark Drive so its protected from theft.

Battery Factory Walkthrough

I was fortunate to have the opportunity to visit the production floor at our battery manufacturing partner in China. In this video i go through the various stations and talk about the process that is occuring at each step. The packs being made here are not for Stark Drive but the processes would be the same.

Hope you found this summary informative and something that peaks your interest for our upcoming launch of Stark Drive Torque.

Stay tuned for my next blog post where i talk about both the painting process with a visit to our painting factory as well as a preview of the working fingerprint recognition on SDT.

Sincerely,

Stark Drive Team

Stark Drive LLC