Stark Drive Torque Manufacturing & Development: Part 2 Battery Factory

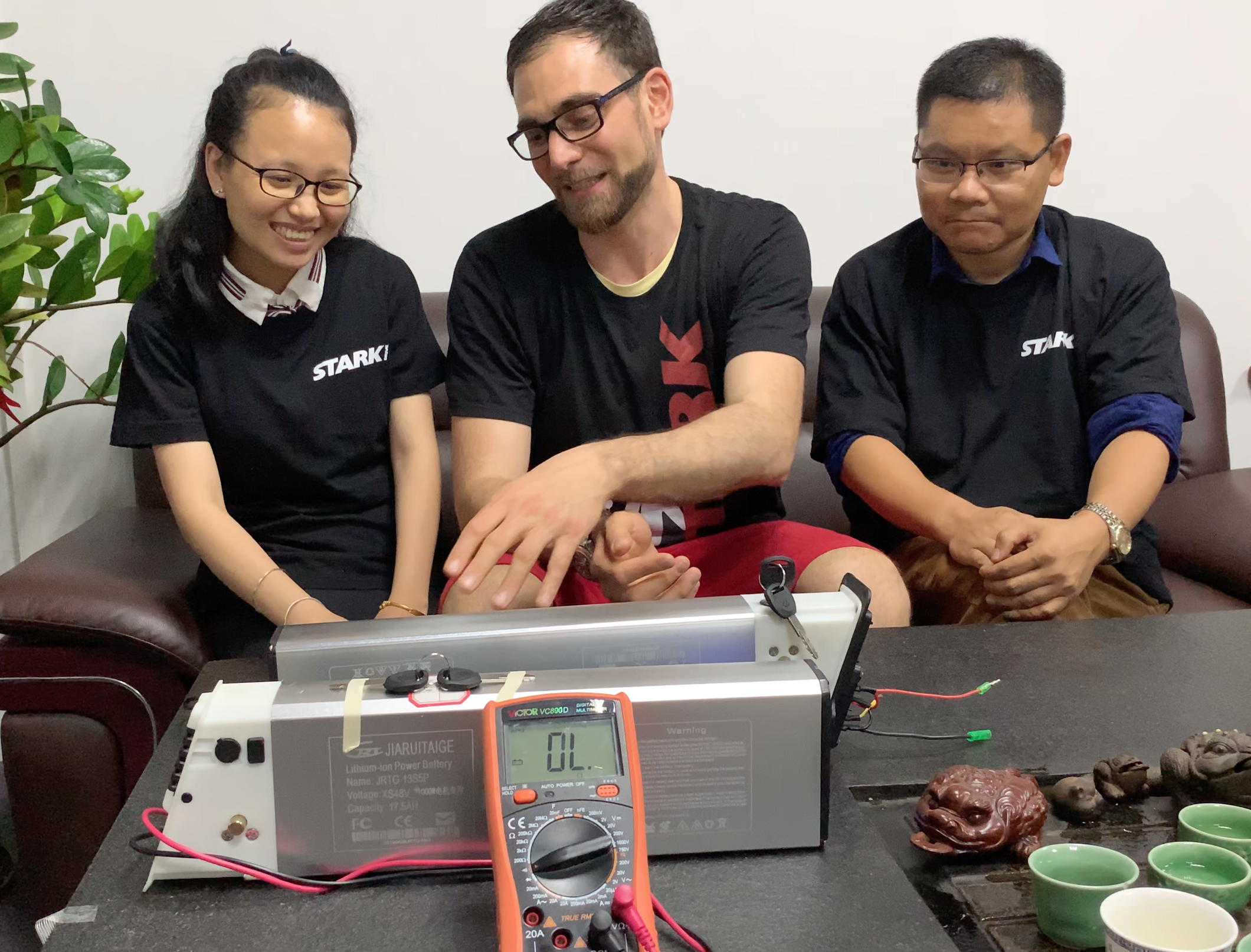

The whirlwind visit to our various factories in china also included a visit to our exclusive battery manufacturing partners whom we have been working with since the launch of the original Stark Drive back in 2017. This factory has been manufacturing ebike batteries for over a decade and has a great deal of experience when it comes the technology behind a perfectly designed and long lasting battery pack.

A battery pack is not simply just a bunch of cells connected in series and parallel and in fact has a lot of circuitry and software that continually senses the state of the battery pack making sure that the cells do not discharge past their safe limit and that the cell charging cuts off to prevent any over voltage situation for the cells, which can prematurely shorten the life of the pack.

Volts

The battery cells for Stark Drive Torque (SDT) will be imported from Japan and will use the best high capacity cells available which currently include cells from Panasonic, Samsung or LG. We use 18650 cells of varying capacity in order to achieve the rated Ah rating that on the pack. We will be offering three battery capacities for Stark Drive Torque that include 9Ah, 13Ah and 18Ah which will operate at the matching voltage to the bike. It's interesting to know that as you increase the bike systems voltage from 36V to 48V and so on, that you need to add a the equivalent corresponding number of cells in series to achieve the desired voltage. For example, if you needed to achieve a total of 36V using our cells, you would need 10 cells in series, conversely, if you wanted to get up to 48V you then need 14 cells in series.

| 10 | 37.0V |

| 14 | 51.8 V |

Remember though that the actual voltage of your battery will be both higher and lower than the nominal voltage during the discharge cycle. To get the full voltage of a battery when fully charged, multiply the fully charged voltage of each cell (4.2 V for li-ion) by the number of cells. So a 10s battery pack is actually 42.0 V when fully charged. The fully drained voltage would be approximately 3.0 V multiplied by the number of cells in series, which would be 30 V for a 10s pack. Our protection circuitry to prevent under voltage cuts the battery off at 27V meaning that the bike stops working as an electric bike when it drops to near this voltage and in fact if you leave your pack sitting over the winter not having charged it the battery would then go into protection mode and the default charger that we ship with Stark Drive will no longer charge the pack and a special charge is needed. In actuality, most li-ion cells can be drained down to 2.5 V, but there is very little energy left between 3.0 V and 2.5 V and it is healthier for the cells to stop discharging at 3.0 V.

Amps

In order to get the desired Ah rating on the pack, you then have to take groups of these series connected cells and connect them in parallel to reach the desired rating. It then becomes the physical space inside the battery housing that determines what the total Ah rating is on the pack as there is physically only so much space available inside the battery housing. If you wanted a 17Ah battery pack at 48V you would need a housing that is roughly 40% larger than the equivalent 36V pack.

Features and Upgrades

Just as we have with the frame, we have redesigned the battery pack for SDT from the ground up adding both a protective fuse to prevent any damage to the cells no matter if they are in use or during charging as well as a unique USB (fast charging) out enabling you to use the battery pack independently of the bike as a high capacity powerbank no matter where your adventures may take you be it a ride through the city or an excursion off road.

Fingerprint recognition

As we are adding fingerprint recognition to the bike, we are reworking the battery pack keying system so that the key can be removed with the bike on (not the same style as the original Stark Drive). This means that the bike can be left on and the bike can be activated by any previously registered fingerprint meaning you can share the bike with the family or friends. There is a USB port built into the frame to access the fast charging capability on the battery pack as well as one located in the bike computer, one can never have enough USB ports when on the road. The battery locks into the frame just like it did with the original Stark Drive so its protected from theft.

Battery Factory Walkthrough

I was fortunate to have the opportunity to visit the production floor at our battery manufacturing partner in China. In this video i go through the various stations and talk about the process that is occuring at each step. The packs being made here are not for Stark Drive but the processes would be the same.

Hope you found this summary informative and something that peaks your interest for our upcoming launch of Stark Drive Torque.

Stay tuned for my next blog post where i talk about both the painting process with a visit to our painting factory as well as a preview of the working fingerprint recognition on SDT.

Sincerely,

Stark Drive Team

Stark Drive LLC